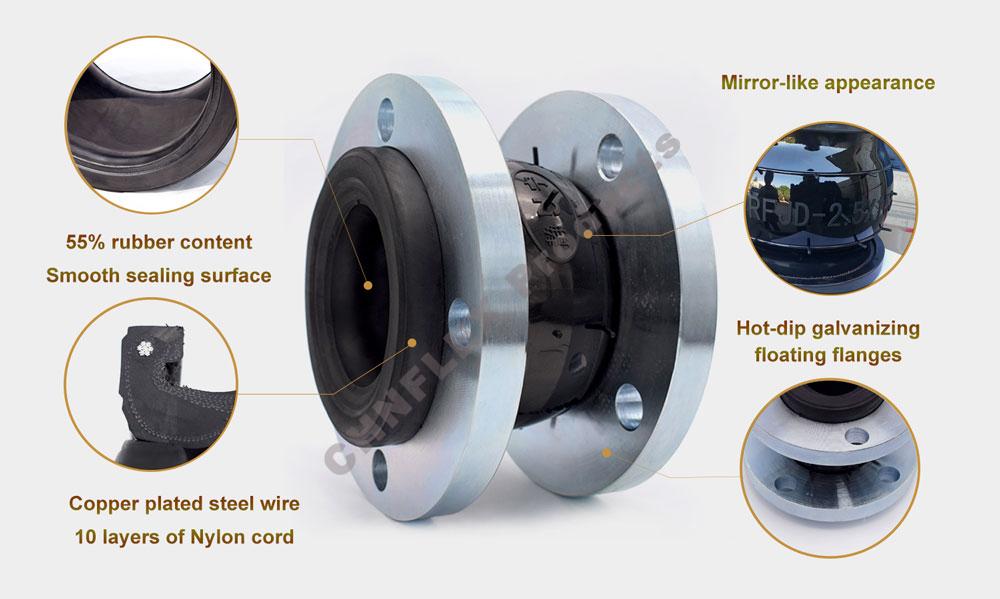

New design epdm single bellow flexible flange type flexible expansion joint

Flexible expansion joints are often referred to as rubber joints. The structural material of the rubber joint is nylon cord fabric, and the inner and outer surfaces are made of high-strength aging resistant polar rubber. In order to prevent the natural shrinkage of flexible expansion joints in long-term use and reduce aging and fracture, steel wires are used for multiple protection of rubber joints. According to different media, the rubber materials used for flexible expansion joints are also different, including NR, SBR, IIR, NBR, EPDM, Cr, fkr, etc. Flexible expansion joints have heat resistance, acid resistance, alkali resistance, corrosion resistance and oil resistance. Flexible expansion joints are widely used in water, electricity, chemical industry and ship mooring systems.

Performance characteristics of flexible expansion joint

1. The flexible expansion joint has the advantages of small size, light weight, good ductility and convenient installation and maintenance.

2. Flexible expansion joint installation can cause horizontal, radial, angular offset, will not be limited by the pipe plug center, flange uneven surface.

3. When the flexible expansion joint is working, it can reduce the structure transmission noise and has strong vibration absorption ability.

Technical data of flexible expansion joint

| Main data of flexible expansion joint | ||||||

| Nominal diameter(DN) | Length | Axial displacement(mm) | Horizontal displacement | Deflexion angle | ||

| mm | inch | mm | Extension | Compression | mm | (a1+a2)° |

| 32 | 1 1/4 | 95 | 6 | 9 | 9 | 15° |

| 40 | 1 1/2 | 95 | 6 | 10 | 9 | 15° |

| 50 | 2 | 105 | 7 | 10 | 10 | 15° |

| 65 | 2 1/2 | 115 | 7 | 13 | 11 | 15° |

| 80 | 3 | 135 | 8 | 15 | 12 | 15° |

| 100 | 4 | 150 | 10 | 19 | 13 | 15° |

| 125 | 5 | 165 | 12 | 19 | 13 | 15° |

| 150 | 6 | 180 | 12 | 20 | 14 | 15° |

| 200 | 8 | 210 | 16 | 25 | 22 | 15° |

| 250 | 10 | 230 | 16 | 25 | 22 | 15° |

| 300 | 12 | 245 | 16 | 25 | 22 | 15° |

| 350 | 14 | 255 | 16 | 25 | 22 | 15° |

| 400 | 16 | 255 | 16 | 25 | 22 | 15° |

| 450 | 18 | 255 | 16 | 25 | 22 | 15° |

| 500 | 20 | 255 | 16 | 25 | 22 | 15° |

| 600 | 24 | 260 | 16 | 25 | 22 | 15° |

Note: 1. The special requirements of flexible expansion joint can be customized according to user's drawing. Flange standard is GB / t9115.1-2000. Various flange standards (GB, JB, Hg, CB, ANSI, DIN, BSEN, NF, en, JIS, ISO, etc.) can be selected for production. The rubber ball of flexible expansion joint can be used as natural rubber, EPDM, chloroprene rubber, butyl rubber, butadiene rubber, fluororubber, etc. when the flexible expansion joint above DN200 is used for suspension water supply, the pipeline must have fixed support or fixed support, otherwise the flexible expansion joint shall be installed with anti falling device.

Flexible expansion joint details show

flexible expansion joint production Flow

Do you know how is a flexible expansion joint made?Let's see with JINGNING.

It is very important to select the appropriate flexible expansion joint, to understand the compatibility of the medium and the selected material of the flexible expansion joint, the range of full temperature, full pressure and full vacuum, the amount of movement required, and the size between the pipe flanges. With this information, Jingning application engineers can help determine the ideal flexible expansion joint for any application.

Flexible expansion joint advantage

1. Factory price of flexible expansion joint.

2. 16 years of manufacturing experience, 5 years of export experience.

3. Strict quality inspection, the quality far exceeds the industry standard.

4. Flexible expansion joint mold has a variety of specifications, support customization, OEM.

5. Provide free samples of flexible expansion joint.

6. Flexible expansion joints are in large stock.

Flexible expansion joint application

Flexible expansion joint is widely used in chemical engineering, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, water heating, fire protection, electric power and other basic projects because of its good comprehensive performance. According to the different rubber materials of flexible expansion joint, it can be made into various varieties, such as acid resistance, alkali resistance, corrosion resistance, oil resistance, high temperature resistance, radiation resistance, wear resistance, aging resistance, etc. the flexible fittings can adapt to a variety of media and environment.

FAQ

Q1:Can the flexible expansion joint be marked with customized logo?

A1:Yes,the flexible expansion joint can be marked with your logo. We could provide OEM&ODM service for flexible expansion joint.

Q2:What’s the face to face length of flexible expansion joint?

A2:The face to face length of flexible expansion joint can be L130, L152,L203... We also could accept customized length according to your requirements.

Q3:Can you provide drawings of flexible expansion joint?

A3:Yes,we could provide drawings of flexible expansion joint for you.Please contact us to get the drawing of flexible expansion joint.

Q4:What certificates of flexible expansion joint can you provide?

A4:We could provide CE,ISO certificate for our flexible expansion joint.

Q5:Can we get a sample of flexible expansion joint?

A5:Yes,we could provide samples for you to test the quality of our flexible expansion joint.